Peter Brigden, General Manager of Termseal Australia, explains the most commonly used types of concrete joints in pre-construction work.

Modern buildings are typically built using concrete, with slab-on-ground construction being a common construction method. They are also typically multi-level, especially in large cities, where buildings are going upwards rather than outwards to minimise their overall footprint.

When constructing buildings using concrete, the process will often involve using joints or changes in components to achieve a particular design. These masonry structures can be challenging for pest managers as vertical and horizontal joints and gaps are all potential access points for termites to gain concealed entry to the building.

Pest managers who undertake pre-construction termite work need to understand the various ways in which concrete is used – particularly concrete joints – in order to successfully minimise the potential for termites to gain entry into buildings as they forage over long distances in search of food. By understanding construction, the expertise of the pest manager is seen as invaluable, as he or she can provide termite management services for any building under construction.

Termseal Australia has developed an outstanding range of products for pest managers to use to manage termites during construction. They have been specifically designed to integrate with masonry construction, whether concrete, brick, block or a combination, with the products able to be used in combination to manage subterranean termite activity in both new and existing buildings.

Here, four types of concrete joints are outlined, with guidance on how to successfully mitigate the risk of termite ingress using Termseal products.

Isolation joint

This type of joint (main picture, above) is designed to allow independent movement between two pieces of concrete so neither is damaged when movement occurs. Inside or outside a building, isolation joints can create man-made alleyways for termites to move through, either vertically or horizontally.

The isolation joint shown in Figure 1 was protected using an application of Termseal’s Prime Coat, Reo-Band FG (non-woven fibreglass mat) and Multi-Purpose Active. This combination offers a durable solution to prevent concealed termite access through the joint. This particular situation was uncommon because the builder had to remove a wall frame as part of the renovation to allow the termite management work to be completed because it was not done after the concrete pour.

Contraction joint

Contraction joints (or control joints) are ‘placed’ in the fresh concrete before it has a chance to create its own joints – also known as cracks. What a contraction joint really is, in the end, is a crack in the slab that we force to follow a line of our own choosing.

Contraction joints are formed by saw cutting, by tooling a joint with a grooving tool, or by inserting a plastic strip into the concrete during finishing (zip-strip). Proper timing and depth of cut are essential; wait too long, and the slab will crack wherever it wants to. If the joint is not cut deep enough it will not create the plane of weakness needed to guide the crack. When the slab does crack along the joint, it is referred to as ‘joint activation’.

Termseal’s Sealant Active can be used after cleaning of the joint to remove loose dust from the cut and after a preparative coat of Prime Coat is applied.

Pest managers will often see ‘CJ’ written on a set of plans, indicating a construction joint. Depending on the location and whether the joints will remain wholly visible, which is rarely the case, then termite management is required to prevent concealed access by termites. This type of joint is a ‘controlled’ full thickness crack of the concrete which, when big enough, can allow termites to travel along (horizontally) and through (vertically).

Expansion joint

An expansion joint in a concrete structure is a disconnection provided between adjacent sections of the concrete slab. This disconnection allows movement due to increases and reductions in the dimensions of the adjacent sections, through which some or all the bonded reinforcement is interrupted. In pavement slabs on ground, it is a separation between slabs filled with a compressible filler material.

An expansion joint would be used where there is a significant risk of concrete movement particularly as a result of bedding soil movement or temperature changes, which could cause the concrete to crack. Pest managers may see them in large outbuildings such as sheds and workshops as well as large commercial buildings.

These are, by their design, full-thickness joints that can enlarge over time and as it cures, the concrete will shrink. Termites will move through either vertically or horizontally if the joint is big enough, so termite management is needed. The use of Termseal’s Multi- Purpose Active between the old and new concrete will reduce the likelihood of termite movement, if applied to the metal strip of the joint before the next pour. Alternatively, the joint can be covered with an application of Multi-Purpose Active after the pour to seal the joint, but this is only an option when the surface will not be subject to foot or vehicular traffic that could wear it down.

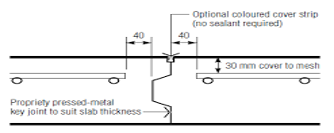

Construction joint

A construction joint is the interface between concrete placements, intentionally created to facilitate construction. Construction joints are formed using some sort of bulkhead, made of wood, steel, plastic, or precast concrete. These bulkheads are often used as screed rails during placement and finishing of the slab.

This type of joint would be used when a large area is being concreted, such as a shed or long driveway, to again control any potential cracking in case of movement up, down or sideways. Movement could, for example, be caused by tree roots growing under a driveway slab in a residential situation. Construction joints could be used in a large commercial building with a floor area over 500 sqm, which needs joints to manage floor stability for the life of the building, so that it can withstand heavy storage and vehicles (especially if it consists of two layers of concrete). The use of Ura-fen Shield TWB 100 mm Joint Filler Strip is an efficient way to manage termite movement in this type of joint, which can be installed between pours.

In 2025, Termseal’s Multi-Purpose termite products celebrate a 20 year anniversary in the Australian industry. The team at Termseal is always available to offer termite professionals assistance in managing termites in any pre-construction situation using Termseal’s trusted and proven products.

Peter Brigden, General Manager, Termseal Australia