Whilst the good old donger still has a place in the inspector’s toolkit, researchers are now investigating more advanced methods of termite detection within timber.

Latest termite detection research

The use of acoustic emission to detect termites

The potential use of acoustic emission (AE) in the wood and timber industry is an active area of research. There are a number of areas where information on the density and structural integrity of wood is needed: wood machining monitoring, wood drying, wood fracture, timber structural health monitoring, termite infestation monitoring and quality control. Technologies that provide quick, accurate, in situ measurement would be of significant value to the industry.

Researchers have just completed a review of AE monitoring of wood materials and timber structures.1 AE has some challenges; there can be a lot of variability in the wood, along with the impact of moisture, which impacts the attenuation, reflection and refraction of the wave. Coupled with variations due to the issues that are the target of the detection device (e.g. termite activity) plus background noise, interpreting the data can also be difficult. Although a lot of research is ongoing in this broad area, the amount focused specifically on termite detection is quite limited. One of the key issues with termite detection is that it needs to be able to detect activity in structural timber within buildings rather than in isolated pieces of timber. As such, additional technical challenges exist in achieving accurate detection on site and condensing the technology into a portable device.

Using microwaves to detect drywood termites

Detecting drywood termites is more of a challenge due to their highly cryptic nature (no mud tubes) and diffuse nest structure (many small nests can be found throughout infested structures). In Australia, drywood termites are not part of the standard termite inspection process, which focuses on subterranean termites (AS 3660.2). To aid with detection, researchers in Queensland have assessed the suitability of using microwaves to detect drywood termite infestations.2

Using the Termatrac device (pictured above) – which uses microwave technology to detect pest presence and movement and is commonly used to detect subterranean termite activity – the researchers confirmed that it could also be useful in the detection of drywood termites. The researchers found that on the highest sensitivity setting, the device detected 97% of West Indian drywood termite infestations, with few false positives. It was sensitive enough to pick up activity even when a single termite was present. However, the detection success depended on the depth and density of the wood. Whilst the device could detect termites to a depth of up to 45 mm in southern pine, it could only detect termites to a depth of 20 mm in denser Tasmanian oak. The researchers concluded that microwave technology (and the Termatrac device) was a suitable tool for use in the detection of drywood termites.

Non-audible acoustic detection of termites

Termites produced audible sounds – it’s possible to hear them chewing wood and hear the ‘head-banging’ of soldier termites when alarmed. However, they also produce a range of sounds that are not audible to the human ear. Technology that can detect and accurately locate termite activity has potential in the detection of termites in buildings. A number of research groups are active in this area.

Researchers in Spain have recently published results looking into the use of piezoelectric sensors with sensitivity in the ultrasound range to detect Reticulitermes activity.3 Using prepared pieces of wood, artificially infested with termites, the research demonstrated that the sensors could detect termite activity, but not differentiate between termite castes (worker or soldier). Furthermore, they determined that by using several sensors, the location of the activity could be pinpointed. However, although the research provided a proof of concept, it was carried out under controlled conditions and the authors noted that variations in real-life situations would affect the results, such as knots in the wood, the presence of resins, cracks and other wood deformities. In addition to condensing the technology into a suitable device or system, the ability to interpret the data and screen out background noise would also be necessary. The authors do note that machine learning models would be useful in this regard.

For more information on how termites are detected during a termite inspection go to our termite inspection page.

References

1 Nasir, Vahid & Ayanleye, Samuel & Kazemirad, Siavash & Sassani, Farrokh & Adamopoulos, Stergios. (2022). Acoustic emission monitoring of wood materials and timber structures: A critical review. Construction and Building Materials. 350. 128877. 10.1016/j.conbuildmat.2022.128877.

2 McDonald, Janet & Fitzgerald, Chris & Hassan, Babar & Morrell, Jeffrey. (2022). Non-destructive Detection of an Invasive Drywood Termite, Cryptotermes brevis (Blattodea: Kalotermitidae), in Timber. 69. 10.13102/ sociobiology.v69i4.7881.

3 Suarez Vargas, Elisabet & Fuentes, Yaiza & Gaju-Ricart, Miquel & Gallego, Antolino. (2023). Non-audible acoustic emission characterization of Reticulitermes termites in pine wood. European Journal of Wood and Wood Products. 81. 10.1007/s00107-023-01948-1.

Termite Professional Australian edition, 2022

Finding timber pests in museums

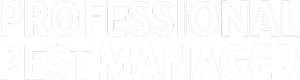

In museums, the main focus of termite detection is on structural timber. However, a niche market exists for the detection of termites and other timber pest activity in high value items such as furniture and picture frames. This is particularly the case in museums where invasive inspection techniques are simply not possible.

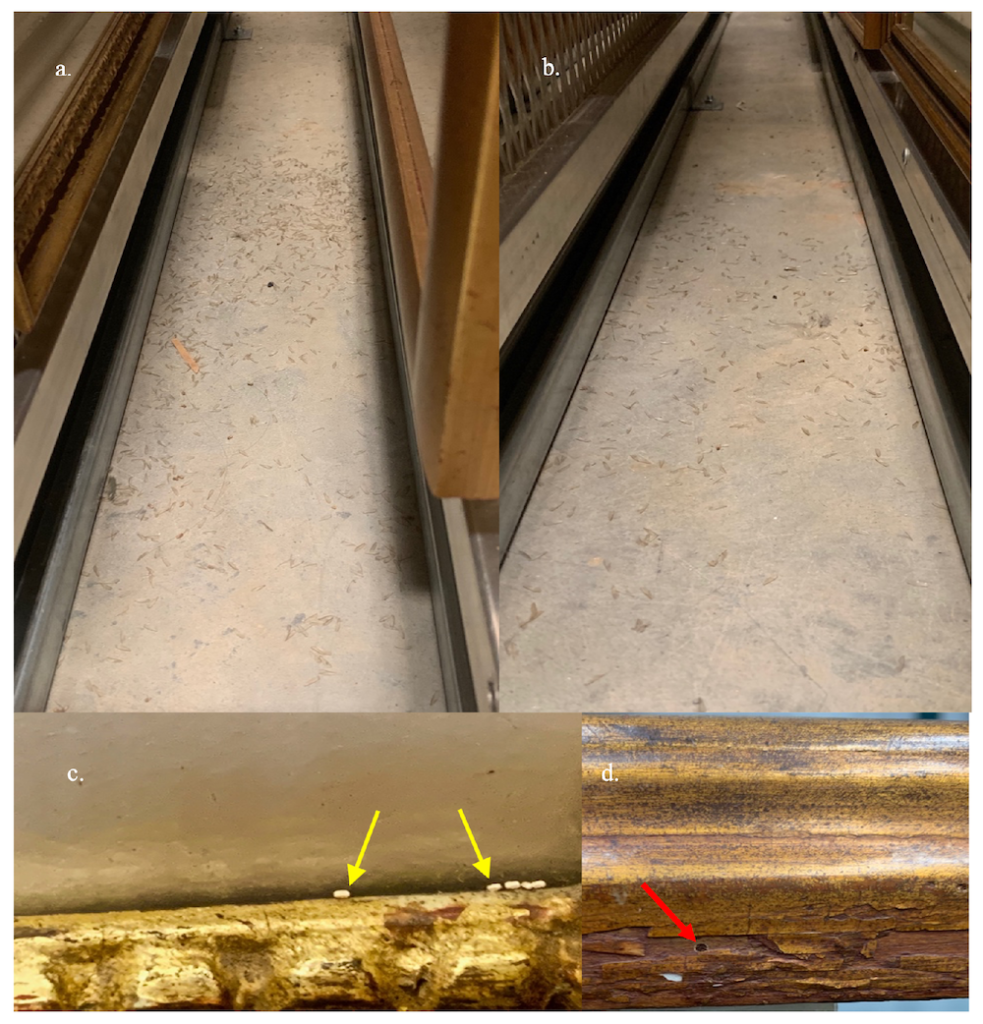

Researchers in the US have recently developed a technique that combines a visual inspection with the use of CT scanning.1 The resulting images not only allow individual insects to be identified (in this case drywood termites in a picture frame) but also enable a full assessment of the item.

The inspection maps any damage and the quantity of wood loss — facts that determine the structural integrity of the frame. Appropriate decisions about treatment, restoration and ongoing management can then be made.

An important side note to this study was that although the museum storage room was held at a certain temperature and humidity level to minimise pest and mould issues, drywood termites were capable of thriving in the storage room for an estimated 15 years.

Powering up timber pest detection

Timber utility poles are a significant component of power and communication networks. Even with preservative treatments they are still susceptible to timber pests over time. However, using timber pest inspectors to assess the health of timber poles can be both inaccurate and time-consuming. As such, research into methods that can help in assessing the strength of power poles and determine the presence of timber pests is of significant value. Recent research has demonstrated that using stress wave propagation coupled with a neural network pattern-recognition algorithm can provide encouraging results, with the three models assessed producing between 81-92% success rates in identifying both healthy and defective poles.2

The ultimate donger

The ‘donger’, really any hard tool for tapping wood, is an essential part of the timber pest inspector’s toolkit. Experienced inspectors use the changes in sound to alert them to potential issues. Now, research has begun on ways to use deep neural networks to analyse the sound that results from hitting a piece of timber, to assess the condition of the timber.3 Using timber blocks with a single, drilled core through the middle, accuracy of the system was up to 92%, regardless of the shape of the timber piece and location of the ‘hit’ on the timber.

Although encouraging, the researchers noted that greater investigation is required. In particular to assess the technology in real-life situations — where damage is enclosed within a piece of timber (rather than a hole drilled all the way through), looking at different types of damage, and in different types of timber. However, unlike the stress wave methodology described previously, which requires a sensor to be installed prior to testing, the researchers believe this technology will allow for the development of a low-cost inspection device that can be used on site.

Improving detection devices

Other researchers have used computer software to investigate ways of improving termite detection devices. Whilst many devices allow for the detection of termites, it is difficult to predict the population size. Researchers identified a list of 40 acoustic and ten temperature features that could be useful in determining the presence of termites and predicting population size.4

Using a Boruta package (an algorithm that can identify the key factors influencing outcomes), this list was refined to 25 acoustic and four temperature features that were relevant. In using the reduced data to detect and assess populations of Coptotermes curvignathus infestations in pine board, the detection accuracy increased to over 97% and improved the accuracy in the prediction of termite population size. The researchers believe this has potential in improving the accuracy of commercial termite detection devices.

References

1 Arbat, Shivani & Forschler, Brian & Mondi, Annelies & Sharma, Ajay. (2021). The Case History of an Insect Infestation Revealed Using X-ray Computed Tomography and Implications for Museum Collections Management Decisions. Heritage. 4. 1016-1025. 10.3390/heritage4030056.

2. Bandara, Sahan & Rajeev, Pat & Gad, E. & Sriskantharajah, Baraneedaran & Flatley, I.. (2021). Structural Health Assessment of Timber Utility Poles Using Stress Wave Propagation and Artificial Neural Network Techniques. Journal of Nondestructive Evaluation. 40. 10.1007/s10921-021-00821-6.

3 Chen, Lin & Xiong, Haibei & Sang, Xiaohan & Cheng, Yuan & Li, Xiuquan & Kong, Qingzhao. (2021). An innovative deep neural network– based approach for internal cavity detection of timber columns using percussion sound. Structural Health Monitoring. 147592172110285. 10.1177/14759217211028524.

4 Achirul Nanda, Muhammad & Seminar, Kudang & Maddu, Akhiruddin & Nandika, Dodi. (2021). Identifying relevant features of termite signals applied in termite detection system. Ecological Informatics. 64. 101391. 10.1016/j.ecoinf.2021.101391.

Termite Professional Australian edition, 2021

Low power microwaves for termite detection

Wooden power poles are susceptible to wood decay and termite attack. Structural failure of power poles can have serious, expensive and potentially life-threatening consequences. The 2014 Perth bushfire that destroyed 57 homes (fortunately with no lives lost) was caused by a power pole failure due to termite damage on private property. Both the property owner and maintenance contractor were held liable. In a bid to minimise the fire risk, Australian researchers have developed a new device that uses very low power microwave energy to detect damaged power poles.

Testing of power pole integrity is somewhat subjective and involves ‘sounding the timber’ using a donger or tapping device, making visual observations and drilling holes to inspect the shavings. Successful assessment is not guaranteed even for experienced termite professionals, but with variable skill levels in pole inspectors, poles with damage are often missed. In addition, drilling into poles not only causes damage, but can itself introduce decay, fungi and sometimes termites into the timber.

Australian researchers evaluated two low power microwaves systems, one a ‘look through’ system that required sensors to be positioned either side of the pole and a second, radar-based system that only has to be positioned on one side of the power pole.1 A key requirement is that the systems need to penetrate the complete depth of the wood (some commercial products can assess wood integrity but only to a depth of a few centimetres).

Both systems work on the principle that the breakdown of wood by termites and wood decay affect the wood structure, in turn affecting the dielectric properties of the wood. This impacts the microwaves passing through the wood and creates a distinct profile compared to sound wood. Both systems were 100% accurate in picking up termite activity and decay. In fact, the radar-based system proved very sensitive, even picking up active termite movement as per other commercial termite detection devices. With assessment of a single pole taking a little over one and half minutes, this technology offers significant benefits to the power utility industry and potentially to the pest management industry as a termite inspection tool.

References

1 Brodie, G., Thanigasalam, D.B., Farrell, P., Kealy, A., French, J.R.J., Ahmed (Shiday), B., 2020. An In-Situ Assessment of Wood-in-Service Using Microwave Technologies, with a Focus on Assessing Hardwood Power Poles. INSECTS 11. https://doi.org/10.3390/insects11090568