John Stewart, Technical Training Manager at Pelsis, offers a helpful guide to dealing with challenging stored product pests.

Australia’s unique climate conditions – from the tropical north to the temperate south – create perfect breeding environments for stored product insects year-round. In a country where food manufacturing contributes over $30 billion annually to the economy, effective pest monitoring isn’t just good practice, it’s essential business protection.

Australian pest management professionals face distinct challenges: our isolated geography means established infestations can spread rapidly through supply chains, our climate extremes support multiple pest generations with minimal seasonal interruption, and our stringent export regulations demand exceptional vigilance. With fines exceeding $100,000 for major food safety breaches, plus the potential for permanent brand damage, early detection through strategic monitoring has never been more critical.

This practical guide focuses on developing monitoring systems tailored to Australian conditions, addressing our common pest species, including warehouse beetle (Trogoderma variabile, main picture above), Indian meal moth (Plodia interpunctella), rust-red grain beetle (Cryptolestes ferrugineus), and the particularly problematic khapra beetle (Trogoderma granarium), a high-priority threat to Australia’s biosecurity.

By implementing the monitoring strategies outlined here, pest managers can not only comply with Australia’s Food Standards Code but also protect their clients’ operations from costly infestations before they take hold.

What follows isn’t just theory – it’s battle-tested methodology developed across thousands of Australian food processing and storage facilities, focusing on early detection to control infestation at an early stage when it is most cost-effective.

The challenge of identification

Food manufacturing and storage sites rely on their pest control service provider to identify the presence of stored product insect (SPI) infestations quickly and accurately, to determine the spread and frequency at which they are being encountered.

SPI infestations can be costly due to the loss of raw product (direct consumption), downgrading of materials (due to physical contamination), product destruction due to it being infected with mycotoxin-producing fungi, product recall, loss of goodwill and brand reputational damage.

Identifying breeding sites

Sometimes, trying to find the breeding sites can be difficult and time-consuming ‘like looking for a needle in a haystack’. Decisions nowadays are all data driven: is the infestation well established? Is it restricted to a specific product or area? The only way to get these answers is by using insect monitoring systems, pheromones and the skills of a knowledgeable pest control technician.

At-risk products should first be identified, with thought given to what species of insect may attack them. What is their feeding strategy? Are they primary feeders capable of attacking undamaged whole product, or secondary feeders infesting milled cereals/seeds? Do the insects crawl or fly? Choosing the correct type of trap or combination of traps is essential, to aid early detection and location of the root cause.

The use of lures and monitors

Strategically positioned monitors with the correct pheromone lures are a fundamental part of any integrated pest management (IPM) program. Once insects have been detected and positively identified, increasing the deployment of monitors is required to find focal points of activity. When product is moving through raw material intakes, machinery, conveyors and packaging lines, infestation can be widespread.

The key is to think small; infestation can emanate from dead spaces within complex production machinery where product gathers, and where powdered product becomes airborne and settles on horizontal surfaces within the building fabric.

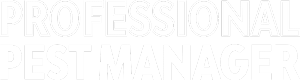

Figure 1 illustrates a warehouse beetle Trogoderma variabile (Ballion) infestation. Pheromone-impregnated delta traps were used to assess insect levels pretreatment (left image). Monitoring after cleaning and treatment allowed for assessment of efficacy (right image). The monitoring demonstrated that the infestation area had reduced and intensity had decreased as a result of the treatment. However, the infestation had not been completely eradicated, with a new hotspot identified.

Understanding the pest life cycle

Warehouse beetles are well established in southern Australia. They are particularly problematic due to their small size, with the adult beetles just 3 mm in length with brown/black mottled marking and short hairs on the wing cases (elytra). They can feed on a wide variety of products, such as seeds, cereals, milk powder, dried dog food, fish meal, spices even other dead insects. The larvae, however, are voracious feeders that cause considerable damage. In addition, the shedding of numerous larval setae (hair-like projections) of Trogoderma spp. can cause irritations in the respiratory and digestive tracts of anyone who breathes or swallows them.

Under optimal conditions, the life cycle of Trogoderma, from egg to adult, is completed in 30 days at 30˚C. The female can deposit more than 90 eggs within infested food. At 32˚C and 50% relative humidity the eggs hatch in six days. The larvae are very mobile and will crawl throughout infested material, infest adjacent foodstuffs and damage food packaging. The larvae go through several moults before pupation.

If natural crevices are not available during pupation they will bore into wood and weak mortar. The pupal stage only requires five days and when environmental conditions are harsh, Trogoderma larvae can enter diapause. Diapause is a resting state during which metabolism slows, and growth stops. The life cycle and biological ability of Trogoderma to resist low humidity, starvation and some common control procedures make them a particularly persistent pest. Adult insects are short lived and do very little damage as they feed on pollen.

With any SPI infestation its always best to reduce the population by performing high level deep cleaning and machine cleans with high efficiency particulate air (HEPA) vacuum cleaners, as this aids in the reduction of food availability, removes eggs, larvae, adults and allergens. The use of air lines to blow powder residue from high level areas should always be avoided as this will spread the infestation by blowing insects around, and their allergens.

Choosing the best products

At Pelsis we have a well trusted and proven brand that manufactures an array of insect monitoring systems and pheromones for different species of stored product insects, bed bugs and public health insects to suit various environments. Our monitoring systems have efficacy data to prove accuracy.

Pest managers interested in the Pelsis range of insect monitors and traps can email the Pelsis team for more information.

John Stewart, Technical Training Manager, Pelsis